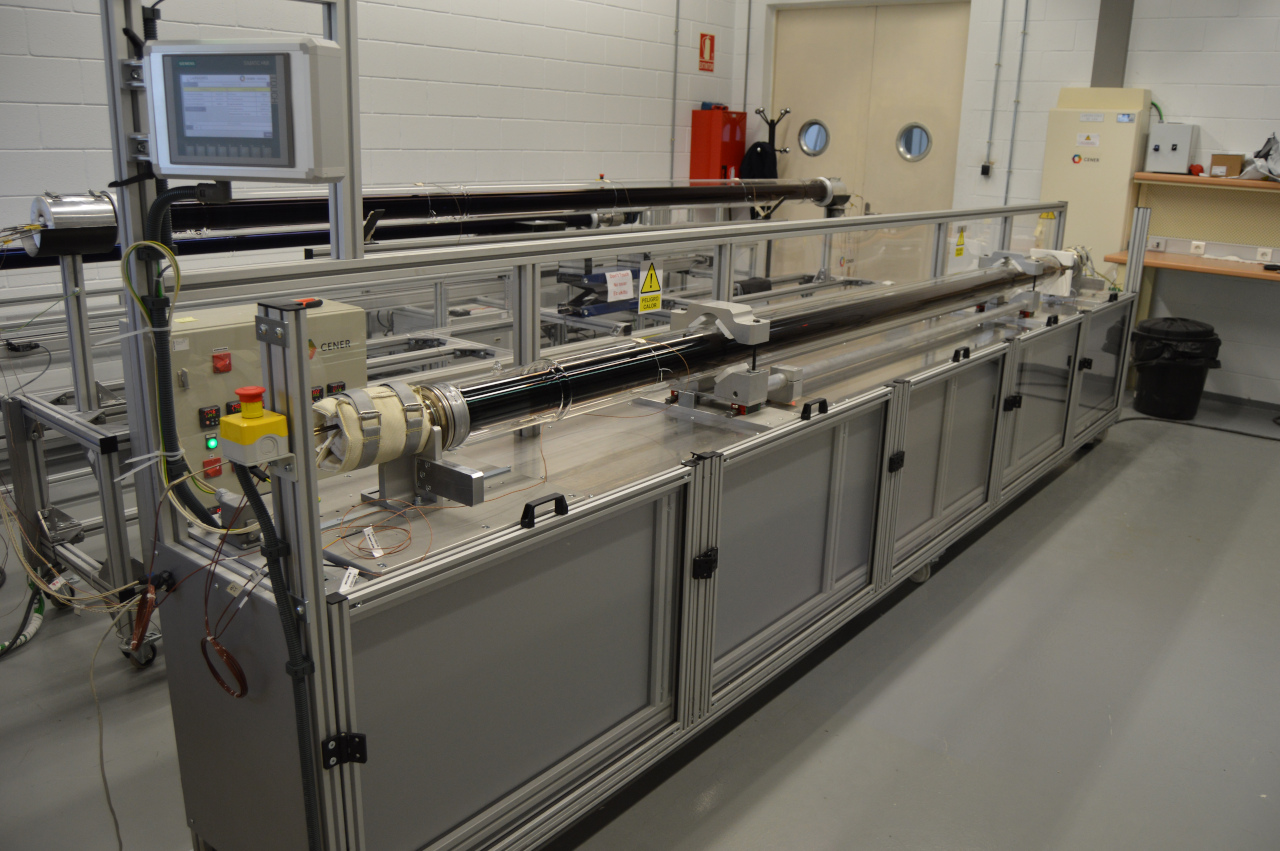

The bellow fatigue test consists of exposing the bellows of the tube to 20.000 cycles of expansion and compression. The absorber tube is first heated to a temperature that allows half of the expansion of the tube (around 200ºC), then the glass tube is subject to push-pull cycles on both sides of the receiver until reaching the maximum stroke of the glass-steel union bellows. The heat losses are repeated after this test to check if the receiver tube has been degraded.

Manufacturer: LARGOIKO

Location: CENER (Sangüesa)